Production

ALMA’s production center is located in Barcelona, in modern facilities of more than 5000 m2, where all the productive activities necessary for the transformation of the product are carried out.

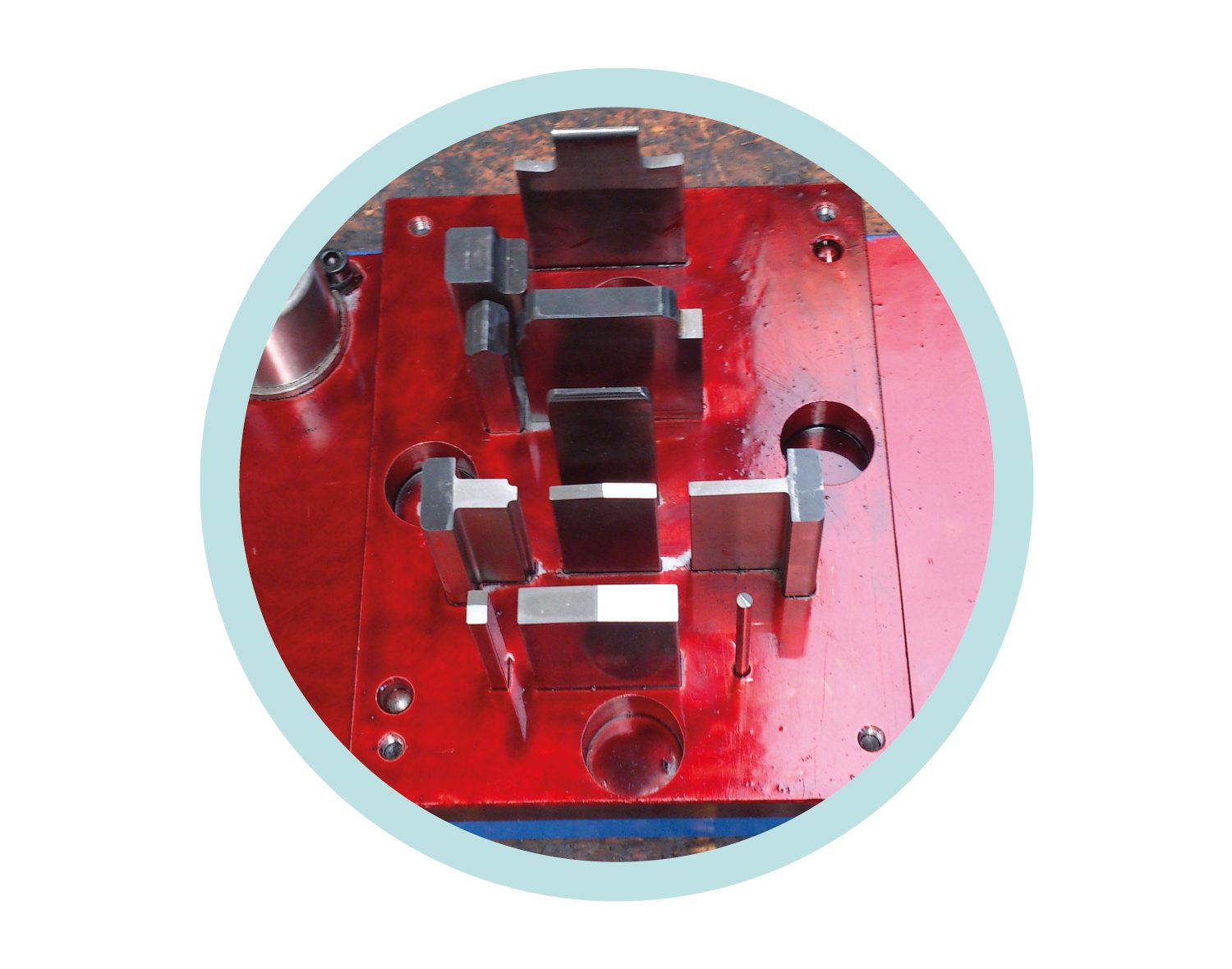

Tooling

In-house workshop for the manufacture of tools, dies and other production and control elements.

The study and design of productive means is integrated into the flow of industrialization of each product.

Having the experience and autonomy for its manufacture, maintenance and repair, allows us to respond sooner and better to production and control needs.

Plastic injection

Belonging to a group makes us better and stronger, allows us to align objectives and generate synergies for a better result. Inject Liquid S.L is undoubtedly the best example of this.

Inject Liquid S.L, belongs to the AXALYS group and from the beginning it is integrated into the development of the products, supplying all the production plants of AXALYS and Alma

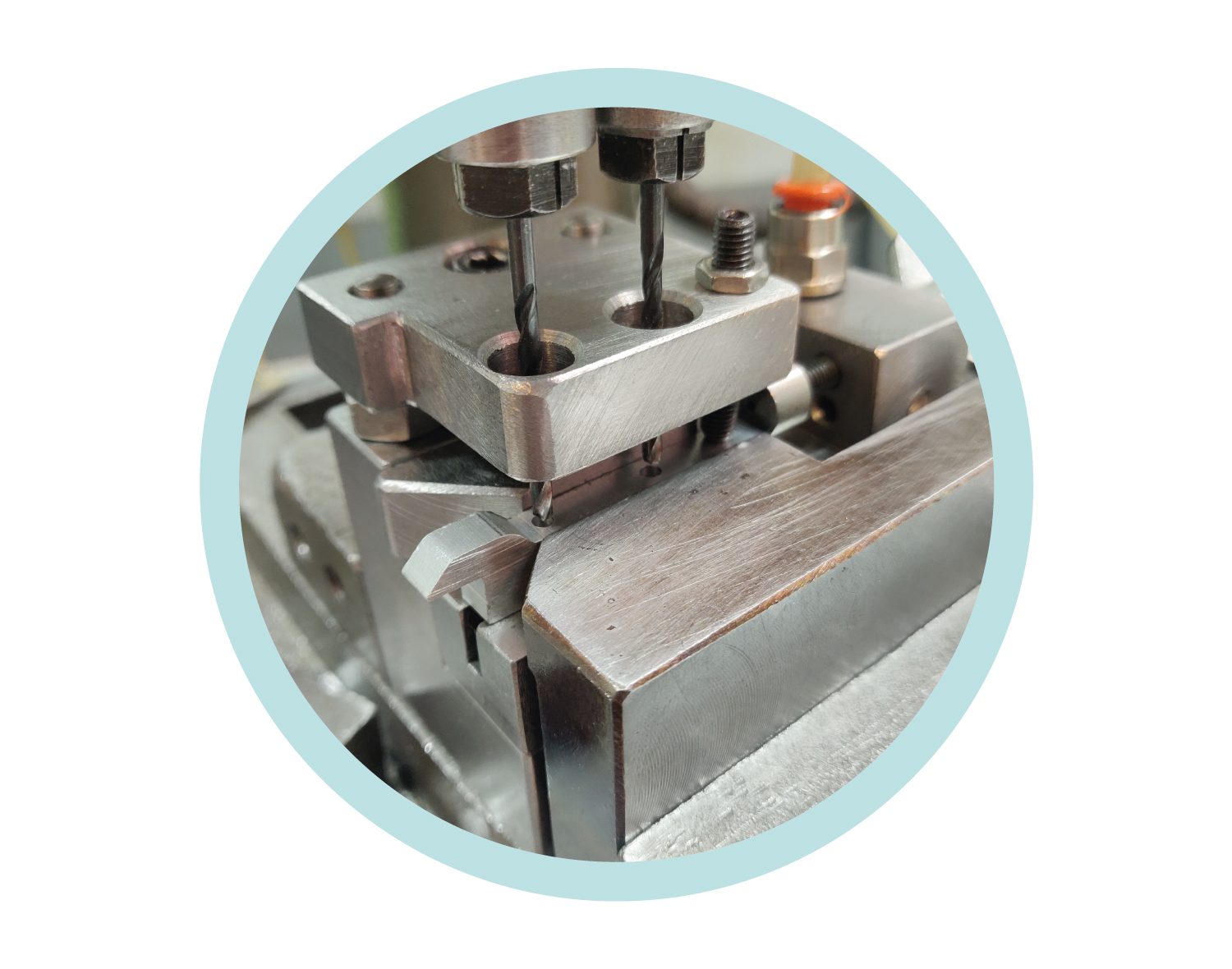

Mechanized

We are equipped with various machining sections such saw cutting, milling, drilling and CNC machining.

Threads

Exclusive section for all types of threads.

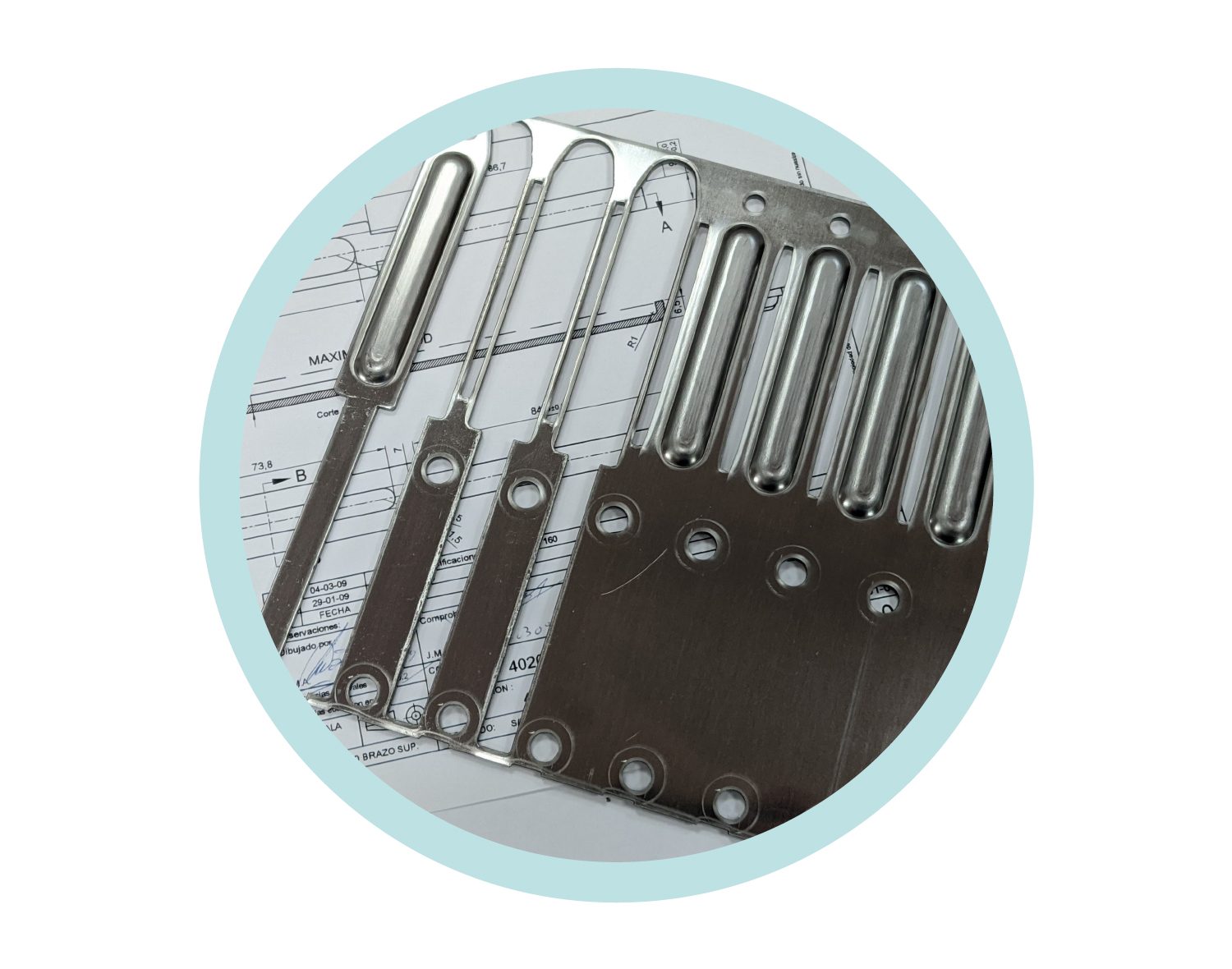

Stamping

We have various several presses for the stamping and embossing of multiple metals

Vibrated and cleaning

In-house section to vibrate, washing and drying of parts.

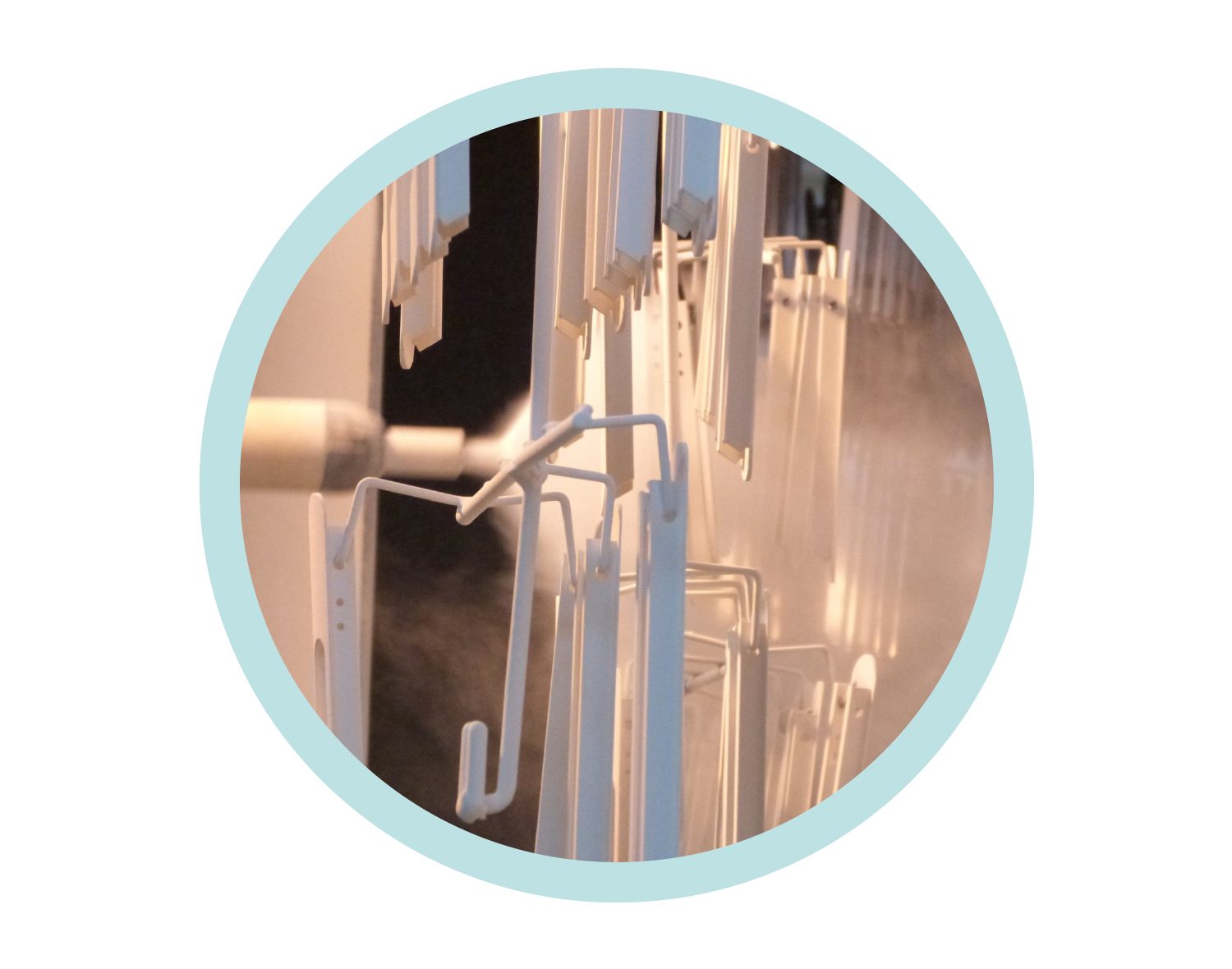

Lacquered

Having our own lacquering facility allows us to control the process and give the best quality.

It also allows us to shorten execution times, easily adapt to market demand and, in general, provide a better service to our customers.

Tampography

Customization option via liquid tampography

Assembly

Assembly section with specific media for each product, from where it manages a network of highly specialized external collaborators.

Packaging

The protection of our products is part of the product itself; it must reach the end customer in the best condition.

Warehouse

Having a large centralized warehouse in the same production center, facilitates the flows and conservation of materials, ensuring optimal delivery times.